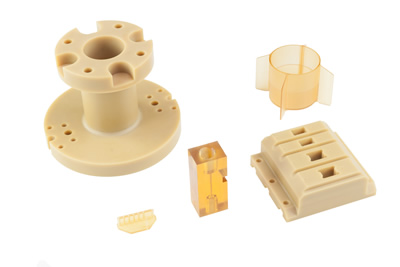

Ultem® Machining

For machined parts requiring added strength, engineers turn to Ultem®. This high-performance thermoplastic is considered one of the best for exhibiting excellent strength and stiffness. Ultem® also maintains great dimensional stability at high temperatures (200°C).

Engineers turn to this material when they need parts machined for demanding applications in the Aerospace industry for aircraft and spacecraft and in Medical industry applications requiring repeated sterilization cycles.

As is the case with many high-performing plastics, understanding the machining characteristics of Ultem® is critical to producing a precision part. Many companies machine Ultem, but it’s critical to work with one that knows how to manage stresses in the material to achieve complex tight tolerance parts.

Why You Should Choose Upland Fab for Ultem® 2300 Plastic Machined Parts

Upland Fab has over 50 years of experience machining Ultem® and other high-performing plastics. We have the quality-driven processes, technology, and equipment needed to achieve the right results.

We create machined parts from Ultem® 2300, a 30% glass fiber reinforced grade. Understanding the abrasiveness and stress properties is even more important when working in this material. Upland Fab machines Ultem 2300 regularly, giving us the experience needed to machine your part correctly the first time.

- Multi-axis machining helps us achieve precise tolerances and ensures your parts are machined correctly the first time with minimal handling and fixturing. Often, even the most complex parts are completed in a single operation.

- Digital Product Definition (DPD/MBD) processes allow us to machine complex Ultem® parts directly from your CAD models. Working directly from CAD models reduces errors and improves accuracy, resulting in decreased costs for your project.

- First-rate communication is a top priority. You’ll have a single point of contact throughout the entire project, giving you constant updates as your project moves forward.

Give us a call at 909-986-6565 to discuss applications for Ultem® machined parts or get a project started today.

Ultem® Thermoplastic Material Properties

Ultem thermoplastic resin comes in several options to meet varying thermal, electrical, physical, and mechanical performance needs. Learn more about Ultem’s different material properties below.

Properties of Ultem® Plastic

| TYPICAL PROPERTIES of Ultem® | |||||||||

| ASTM or UL test | Property |

|

|

|

|

||||

| PHYSICAL | |||||||||

| D792 | Ultem® Density (lb/in³) (g/cm³) | 0.046 1.28 |

0.048 1.34 |

0.051 1.42 |

0.051 1.42 |

||||

| D570 | Water Absorption of Ultem®, 24hrs (%) |

0.25 |

0.21 |

0.19 |

0.18 |

||||

| D570 | Ultem Water Absorption, Saturation (%) |

1.25 |

1.2 |

1.1 |

0.9 |

||||

| MECHANICAL | |||||||||

| D638 |

Ultem® Tensile Strength (psi) |

16,500 |

16,800 |

16,900 |

17,000 |

||||

| D638 | Ultem® Tensile Modulus (psi) | 500,000 | 650,000 | 700,000 | 800,000 | ||||

| D638 |

Tensile Elongation at Break (%) |

80 |

6 |

3 |

3 |

||||

| D790 | Flexural Strength of Ultem® (psi) |

20,000 |

23,000 |

25,000 |

27,000 |

||||

| D790 |

Flexural Modulus (psi) |

500,000 |

- |

- |

850,000 |

||||

| D695 | Compressive Strength of Ultem® (psi) | 22,000 | 24,000 | 28,000 | 32,000 | ||||

| D695 | Compressive Modulus (psi) | 480,000 | - | - | 625,000 | ||||

| D785 | Ultem® Hardness, Rockwell | M122/R125 | M114/R127 | M114/R127 | M114/R127 | ||||

| D256 | IZOD Impact Notched (ft-lb/in) | 0.5 | 0.6 | 0.8 | 1 | ||||

| THERMAL | |||||||||

| D696 | Coefficient of Linear Thermal Expansion for Ultem (x10-5 in./in./°F) |

3.1 | 1.8 | 1.4 | 1.1 | ||||

| D648 | Heat Deflection Temp (°F/°C) at 264 psi for Ultem |

400 / 204 | 405 / 207 | 408 / 208 | 410 / 210 | ||||

| D3418 | Glass Transition Temp (°F/°C) | 410 / 210 | 410 / 210 | 410 / 210 | 410 / 210 | ||||

| - | Max Continuous Operating Temp of Ultem® (°F/°C) | 340 / 171 | 340 / 171 | 340 / 171 | 340 / 171 | ||||

| C177 | Thermal Conductivity (BTU-in/ft²-hr-°F) (x10-4 cal/cm-sec-°C) |

0.85 2.93 |

1.22 4.2 |

1.43 4.93 |

1.56 5.37 |

||||

| UL94 | Flammability Rating of Ultem® | V-0 | V-0 | V-0 | V-0 | ||||

| ELECTRICAL | |||||||||

| D149 | Dielectric Strength of Ultem® (V/mil) short time, 1/8" thick | 830 | - | - | 770 | ||||

| D150 | Dielectric Constant at 1 MHz | 3.15 | 3.5 | 3.5 | 3.7 | ||||

| D150 | Dissipation Factor at 1 MHz | 0.0013 | 0.0014 | 0.0015 | 0.0015 | ||||

| EOS/ESD S11.11 | Surface Resistivity (ohms/square) | 10^13 | 10^13 | 10^13 | 10^13 | ||||

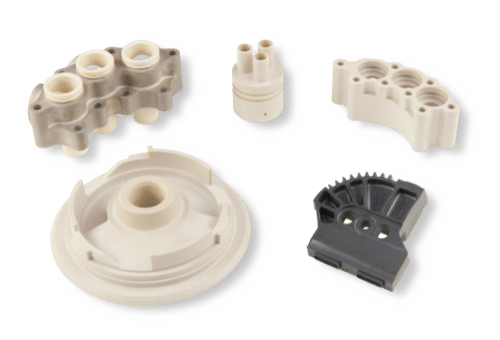

CNC Technologies for Machining Ultem® Plastic

Upland Fab utilizes multi-axis machining to produce Ultem plastic parts. Our state-of-the-art CNC machining technology enables us to manufacture your components with minimal handling and fixturing requirements. In most cases, even the most intricate parts can be completed in a single operation, significantly reducing turnaround times.

Our machining capabilities include:

Additionally, our DPD/MBD processes (Digital Product Definition/Model-Based Definition) allow us to work directly from your digital CAD models. By leveraging your design files, we eliminate machining errors and improve the accuracy and precision of the resulting parts. This ensures better quality parts at lower prices.

Other High-Performance Materials We Work With

Are you looking for another material? Here’s a look at some of the other plastics we work with.

|

|

||

|

|

||

|

|

|

|

Discover the Upland Fab Edge and Contact Us Today!

Experience the difference of working with an industry-leading plastic machining company. Contact Upland Fab or submit a Request for Quote to discuss your upcoming Ultem machining project.