The Annealing Process of Plastics

The annealing process is performed on plastics to remove stress that could result in the finished product cracking, wearing, poor chemical resistance, or performance degradation. Mechanical processes like molding, casting, extrusion, cutting, and drilling cause further stress in plastics. By annealing machined plastics, you can relieve inner pressures on the material to provide higher dimensional stability over time.

Since 1970, Upland Fab has built a reputation for high-performing, reliable plastics manufacturing. We ensure quality through our advanced in-house annealing capabilities, state-of-the-art machinery services, and can-do attitude. Contact us or request a quote to learn more about what our team of problem solvers can do for you.

High-Quality Annealing for Long-Lasting Plastic Parts

The annealing plastic process involves heating a part up to half of the melt temperature before cooling the part back down, allowing the plastic to relax. The in-house process at Upland Fab ensures longevity and quality in our plastic parts. Our process involves:

- Determining the Proper Temperature and Time: The temperature and time spent in the annealing process differ depending on the plastic used as different materials experience softening at different temperatures. We determine the best temperature and duration of annealing for your part.

- Tailoring the Annealing Process to a Specific Plastic Part: As annealing can occur before or after machining and finishing, we pinpoint the best time to start your plastic part’s annealing cycle and customize the racking system. At all stages, Upland Fab individualizes the process to meet your part’s exact needs.

- Performing the Specific Annealing Cycle: Our expert engineers slowly heat the plastic material to just below the specific plastic’s softening point and hold the material there as long as necessary. We then slowly lower the temperature until the part reaches room temperature.

The Benefits of Annealing Plastic Parts

Upland Fab’s plastic annealing process offers many short-term and long-term advantages. These benefits include:

- Increased dimensional stability

- Improved integrity

- Reduced shrinkage and expansion

- Improved chemical resistance

- Tighter tolerance capability

- Improved wear resistance

Annealing Polymers for Any Industry or Application

We anneal plastic to manufacture complex parts for a wide range of industrial applications. These industries include:

No matter your industry, we understand your need for highly accurate and precise components. Our in-house plastic annealing services and state-of-the-art machining capabilities enable us to produce parts that meet all specifications on time, every time.

Why Choose Upland Fab for Your Plastic Annealing & Manufacturing Needs?

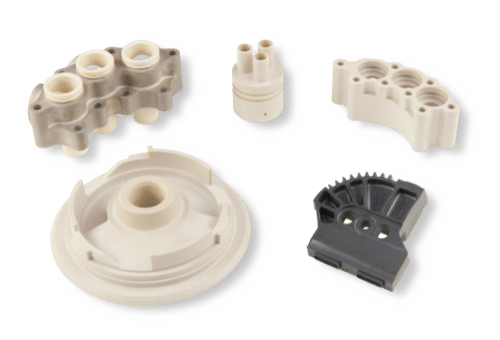

At Upland Fab, we specialize in machining various polymer materials, precision plastics, and composites to manufacture complex parts and components. We are an ISO 9001:2015 and AS9100 Rev D certified manufacturer with customer service that is second to none. Our machining capabilities include:

Customer Communication & Inventory Management

As a customer of Upland Fab, you’ll have a single point of contact who will be with you every step of the way. In addition, we have an efficient and advanced Supply Inventory Management system, so you’ll never have to worry about reorders or running out at the wrong time! We can work with any delivery frequency, whether it’s daily, weekly, or monthly. Flexibility in our manufacturing enables us to adjust shipping quantities and frequencies as needed to meet changes in product demand.