PVDF Machining

PVDF plastic, also known as polyvinylidene fluoride or Kynar®, is a high molecular weight crystalline thermoplastic polymer. It exhibits excellent abrasion, chemical, and flame resistance and high UV stability. Upland Fab has been working with this unique material for years and provides precision machined PVDF plastic parts and components for all applications.

Features & Benefits of Polyvinylidene Fluoride Materials

- PVDF plastic, being corrosion and chemical resistant, is very tough and durable, with good thermal stability in operating temperatures as high as 300°F (149°C)

- PVDF plastic offers high tensile strength and high impact resistance, and is easy to weld using thermoplastic welding technology.

Polyvinylidene fluoride is available in homopolymer and copolymer formulations

- Homopolymer PVDF plastic provides higher strength and stiffness and greater heat deflection than copolymer PVDF

- Copolymer PVDF plastic is less stiff than the homopolymer variety, but offers greater impact and stress crack resistance

Applications of PVDF Plastic

The unique properties of PVDF plastic make it an ideal material for a broad range of uses. Common applications include:

- chemical tank liners and process equipment

- semiconductor components

- pipe flanges

- fittings

- seals

- gaskets

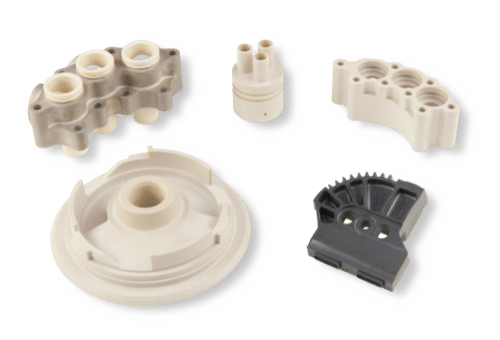

Precision PVDF Machining

Upland Fab utilizes multi-axis machining to produce PVDF parts. Our state-of-the-art CNC machining technology enables us to manufacture your components with minimal handling and fixturing requirements. In most cases, even the most intricate parts can be completed in a single operation, significantly reducing turnaround times.

Our machining capabilities include:

Additionally, our DPD/MBD processes (Digital Product Definition/Model-Based Definition) allow us to work directly from your digital CAD models. By leveraging your design files, we eliminate machining errors and improve the accuracy and precision of the resulting parts. This ensures better quality parts at lower prices.

Properties of PVDF Plastic

| ASTM or UL test | Property | Kynar® PVDF |

| PHYSICAL | ||

| D792 | Density (lb/in³) (g/cm³) |

0.064 1.77 |

| D570 | Water Absorption, 24 hrs (%) | 0.03 |

| MECHANICAL | ||

| D638 | Tensile Strength (psi) | 6,300 |

| D638 | Tensile Modulus (psi) | 290,000 |

| D638 | Tensile Elongation at Break (%) | 50 |

| D790 | Flexural Strength (psi) | 9,700 |

| D790 | Flexural Modulus (psi) | 290,000 |

| D695 | Compressive Strength (psi) | 9,000 |

| D695 | Compressive Modulus (psi) | - |

| D2240 | Hardness, Shore | D75 |

| D256 | IZOD Notched Impact (ft-lb/in) | 3.0 |

| THERMAL | ||

| D696 | Coefficient of Linear Thermal Expansion (x 10-5 in./in./°F) |

6.6 |

| D648 | Heat Deflection Temp (°F / °C) at 264 psi |

230 / 110 |

| D3418 | Melting Temp (°F / °C) | 332 / 166 |

| - | Max Operating Temp (°F / °C) | 275 / 130 |

| C177 | Thermal Conductivity (BTU-in/ft²-hr-°F) (x 10-4 cal/cm-sec-°C) |

1.2 4.1 |

| UL94 | Flammability Rating | V-O |

| ELECTRICAL | ||

| D149 | Dielectric Strength (V/mil) short time, 1/8" thick | 1700 |

| D150 | Dielectric Constant at 1 MHz | 8.5 |

| D150 | Dissipation Factor at 1 MHz | 0.05 |

| D257 | Volume Resistivity (ohm-cm)at 50% RH | 1.5 x 1015 |

[Polyvinylidene Fluoride material chart]

Upland Fab Top-Flight Communication Keeps You Informed

Good communication is crucial in any project. That’s why, when you work with us, you’ll have a single point of contact throughout the entire process, and you’ll receive consistent, reliable updates that will keep you up to speed on your project’s progress.

Other Materials We Work With

Are you looking for another material? We have the ability to machine many different materials take a look below at some of the other plastics we work with.

|

|

|

|

||

|

|

|

Contact Us to Learn More About PVDF Plastic Machining

Since 1970, customers throughout Southern California have turned to Upland Fab for top-flight plastic and composite machining. Contact Upland Fab for more information, or get a quote on the PVDF plastic parts you need.