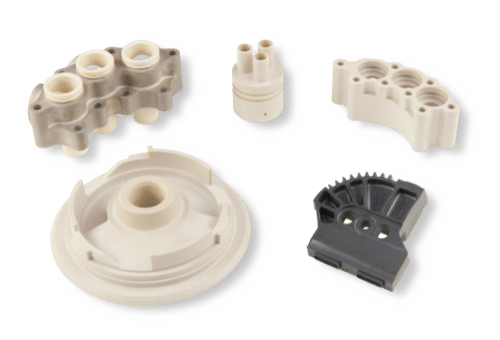

Plastic CNC Turning

Most CNC turning companies that manufacture plastic parts rely on 3D printing or injection molding, while other CNC shops only work with metal. Upland Fab offers you the perfect blend of experience with both CNC turning and plastics manufacturing. As an industry leader in precision plastics manufacturing, we are committed to producing high-quality, reliable parts that can withstand the demands of industrial and commercial CNC turning applications.

Our experienced engineers and in-house trained technicians can take your complex geometries and turn them into top-quality parts. We are unrivaled when it comes to precision machining capabilities. With over 40 years of experience, we offer you the quality and reliability you need for your next CNC turning project.

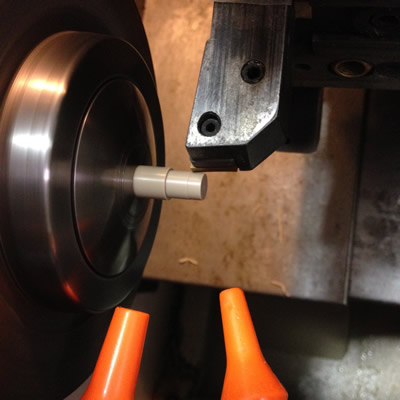

CNC Plastic Part Turning Equipment Technologies

At our facility, we operate a full complement of plastic CNC turning equipment, ranging from basic 2- and 3-axis lathes to a revolutionary 8-axis mill-turn center.

The 8-axis mill-turn center combines a 3-axis lathe with a 5-axis CNC mill to machine complex parts in a single setup. It makes unattended machining possible and significantly decreases lead times. Upland Fab is one of the only plastics manufacturer that has an 8-axis mill-turn center. You will be hard-pressed to find and experience the benefits of this innovative technology anywhere else.

As a CNC turning parts manufacturer, we specialize in low volume plastic part production runs. Our low volume manufacturing offers you design flexibility and techniques that can be optimized for your plastic part or product.

Industry Applications for CNC Turning

Throughout our tenure as a plastics and composites machining company, we have worked with a variety of industries. From aerospace to medical and everything in between, we understand what it means to work with industry-specific requirements.

For instance, aerospace and defense industries have extremely stringent guidelines for products and manufacturing. In addition to product quality and reliability, there must also be a focus on performance, design, and function. Our 8-axis mill-turn center provides the best solution for applications that require accuracy and precision.

Advantages of Using CNC Plastic Part Turning

Injection molding, rapid prototyping, and 3D printing can’t compete with CNC turning in terms of accuracy. As a plastic CNC turning manufacturer, we achieve much tighter tolerances than are possible with other manufacturing methods.

CNC turning is also effective for a much broader range of materials. At Upland Fab, we use CNC turning to machine plastic parts from materials such as Vespel®, Teflon®, carbon-fiber composites and many others.

Because it’s highly efficient, CNC turning is far more cost-effective than injection molding or rapid prototyping.

Customer Communication and Inventory Management

As a customer of Upland Fab, you’ll have a single point of contact who will be with you every step of the way. In addition, we have an efficient and advanced Supply Inventory Management system so you'll never have to worry about reorders or running out at the wrong time! We can work with any delivery frequency, whether it’s daily, weekly, or monthly. Flexibility in our manufacturing enables us to adjust shipping quantities and frequencies as needed to meet changes in product demand.