Nylon CNC Machining

One of the more common thermoplastic materials, nylon is strong, stiff, and very lightweight, with outstanding bearing and wear properties. Nylon is also sometimes refered to as Zytel, which is the trademark name from DuPont. Zytel or nylon is used for a number of different high strength, abrasion and impact resistant thermoplastic polyamide formulations. As such, it is often used as a material replacement for metals such as bronze, brass, and steel, as well as wood, rubber, and other plastics. Nylon plastics are relatively easy to work with, and Upland Fab has decades of experience working with these materials. We can deliver the complex, high precision nylon parts and components you need.

with, and Upland Fab has decades of experience working with these materials. We can deliver the complex, high precision nylon parts and components you need.

Benefits of Using Nylon Plastics

In addition to the above-mentioned properties, nylon plastics also exhibit good resistance chemicals, alkalis, dilute acids, and oxidizing agents, good wear resistance, a high modulus of elasticity, and high resistance to impact, abrasion, and vibration. Nylon thermoplastic parts offer significant noise reduction over metal parts, and induce less wear on mating parts.

Nylon plastics are available in a broad range of grades and formulations, each of which exhibits unique characteristics that may be better suited to your specific application. Contact us to discuss your material requirements.

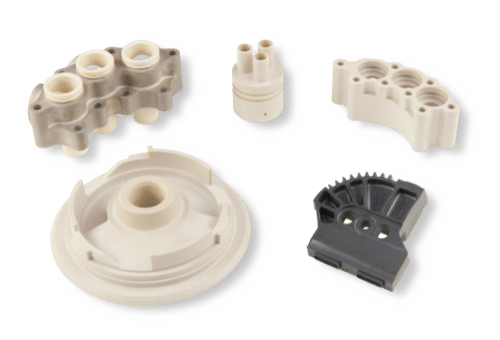

Precision-Machined Nylon Thermoplastic Parts

Upland Fab utilizes multi-axis machining to produce high-precision nylon thermoplastic parts. Our state-of-the-art CNC machining technology enables us to manufacture your components with minimal handling and fixturing requirements. In most cases, even the most intricate parts can be completed in a single operation, significantly reducing turnaround times.

Our machining capabilities include:

Additionally, our DPD/MBD processes (Digital Product Definition/Model-Based Definition) allow us to work directly from your digital CAD models. By leveraging your design files, we eliminate machining errors and improve the accuracy and precision of the resulting parts. This ensures better quality parts at lower prices.

Properties of Nylon Thermoplastic

| ASTM or UL test | Property | Nylon 6 MC907,901 Unfilled |

Nyloil Oil-Filled |

Nylatron GSM Moly-Filled |

Nylatron GSM Blue Moly & Oil |

Nylatron NSM Solid-Lube |

| PHYSICAL | ||||||

| D792 | Density (lb/in³) (g/cm³) |

0.042 1.15 |

0.042 1.16 |

0.042 1.16 |

0.042 1.15 |

0.042 1.15 |

| D570 | Water Absorption, 24 hrs (%) Saturation (%) |

0.3 7.0 |

0.5 2.5 |

0.3 7.0 |

0.22 - |

0.25 7.0 |

| MECHANICAL | ||||||

| D638 | Tensile Strength (psi) | 12,000 | 10,000 | 10,500 | 10,000 | 11,000 |

| D638 | Tensile Modulus (psi) | 400,000 | 425,000 | 400,000 | 500,000 | 410,000 |

| D638 | Tensile Elongation at Break (%) | 20 | 50 | 30 | 35 | 20 |

| D790 | Flexural Strength (psi) | 16,000 | 15,000 | 16,000 | 15,000 | 16,000 |

| D790 | Flexural Modulus (psi) | 500,000 | 425,000 | 400,000 | 425,000 | 400,000 |

| D695 | Compressive Strength (psi) | 15,000 | 13,000 | 14,000 | 13,000 | 14,000 |

| D695 | Compressive Modulus (psi) | 400,000 | 325,000 | 400,000 | 425,000 | 400,000 |

| D785 | Hardness, Rockwell R | R115 | R110 | R110 | R117 | R115 |

| D256 | IZOD Notched Impact (ft-lb/in) | 0.4 | 1.6 | 0.5 | 0.9 | 0.5 |

| THERMAL | ||||||

| D696 | Coefficient of Linear Thermal Expansion (x 10-5 in./in./°F) |

3.5 | 3.5 | 3.5 | 5.9 | 5.0 |

| D648 | Heat Deflection Temp (°F / °C) at 264 psi | 200 / 93 | 350 / 177 | 200 / 93 | - | 200 / 93 |

| D3418 | Melting Temperature (°F / °C) | 420 / 215 | 450 / 232 | 420 / 215 | 420 / 215 | 420 / 215 |

| - | Max Operating Temp (°F / °C) | 200 / 93 | 230 / 110 | 200 / 93 | 200 / 93 | 200 / 93 |

| C177 | Thermal Conductivity (BTU-in/ft²-hr-°F) (x 10-4 cal/cm-sec-°C) |

- - |

- - |

- - |

- - |

- - |

| UL94 | Flammability Rating | HB | - | HB | - | HB |

| ELECTRICAL | ||||||

| D149 | Dielectric Strength (V/mil) short time, 1/8" thick | 500 | 550 | 400 | - | 400 |

| D150 | Dielectric Constant at 60 Hz | 3.7 | 3.7 | 3.7 | - | - |

| D150 | Dissipation Factor at 60 Hz | - | - | - | - | - |

| D257 | Volume Resistivity (ohm-cm) at 73°F, 50% RH | > 1013 | - | > 1013 | > 1013 | > 1013 |

[Nylon material chart]

Stay Up to Date with Upland Fab’s Top-Flight Communication

When you work with Upland Fab, you’ll have a single point of contact throughout your entire project. We know that timely communication is critical, and we’ll provide consistent, reliable updates to keep you informed on the progress of your project. We give you all the information you need, and the peace of mind you want.

Other Materials We Work With

Are you looking for another material? We have the ability to machine many different materials take a look below at some of the other plastics we work with.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Contact Upland Fab to Learn More About Nylon Plastic Machining

We have been providing top-flight plastics and composite machining in Southern California since 1970. Contact Upland Fab to learn more, or get a quote to get started on your project.