G10 FR4 Machining

G10/FR4 Machining Epoxy Resin

A type of phenolic laminate, FR4 glass epoxy is produced by applying heat and pressure to multiple layers of disparate specialty materials which have been impregnated with synthetic thermosetting resins. The heat and pressure polymerizes the individual layers into a single, laminated material.

A type of phenolic laminate, FR4 glass epoxy is produced by applying heat and pressure to multiple layers of disparate specialty materials which have been impregnated with synthetic thermosetting resins. The heat and pressure polymerizes the individual layers into a single, laminated material.

Like other phenolic laminates, G10/FR4 electrical grade epoxy resin is extremely strong and stiff. FR4 glass fabric also exhibits a low coefficient of thermal expansion and outstanding electrical properties, making it an ideal material for electronic and electromechanical components. It is flame retardant and, with very low moisture absorption, is well-suited to use in high-humidity environments, and one of our most trusted laminate products we work with.

We also work extensively with G11 epoxy resin.

Precision Fiberglass Materials to Match Your Industry’s Needs

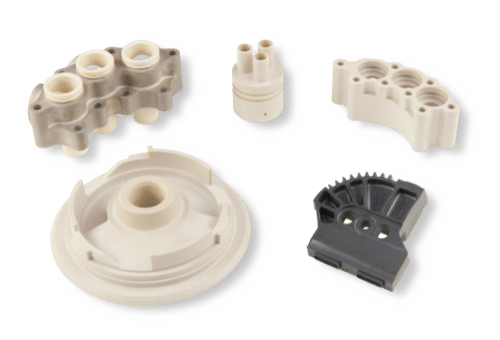

G10 fiberglass and FR4 epoxy are well suited to an extensive range of industrial productions. Common uses include medical manufacturing, defense productions, and much more.

- Medical: G10 and FR4 feature excellent mechanical strength and insulation properties, making them a good choice for machining parts used in diagnostic equipment, implantable devices, surgical implements, and more.

- Defense: As G10 and FR4 materials are lightweight, strong, and withstand demanding environments, they are commonly used in structural components and insulation throughout defense applications.

- Semiconductor & Electronics: Due to the material’s extremely good insulation capabilities, G10 fiberglass is ideal for manufacturing safe and effective battery systems, insulation, and other electrical parts.

- Aerospace: Aerospace components must be lightweight but resilient. G10/FR4 is commonly used to manufacture aircraft parts, radar systems, and similar components.

G10 Machining Fiberglass

Upland Fab utilizes multi-axis machining to produce G10 parts. Our state-of-the-art CNC machining technology enables us to manufacture your components with minimal handling and fixturing requirements. In most cases, even the most intricate parts can be completed in a single operation, significantly reducing turnaround times.

Our machining capabilities include:

Additionally, our DPD/MBD processes (Digital Product Definition/Model-Based Definition) allow us to work directly from your digital CAD models. By leveraging your design files, we eliminate machining errors and improve the accuracy and precision of the resulting parts. This ensures better quality parts at lower prices.

Dedicated Account Managers

At Upland Fab, we make communication a top priority. We provide consistent, reliable communication, with a single point of contact throughout your whole project, to keep you up to date as your project progresses. We stay in touch every step of the way.

FR4 Epoxy Material Properties

| ASTM or UL test | Property | G-3 | G-5/G-9 | G-7 | G-10 | G-11 |

| PHYSICAL | ||||||

| D792 | Density (lb/in³) (g/cm³) |

0.065 1.80 |

0.067 1.85 |

0.065 1.80 |

0.065 1.80 |

0.065 1.80 |

| D570 | Water Absorption, 24 hrs (%) | 2.65 | 0.60 | 0.10 | 0.10 | 0.20 |

| MECHANICAL | ||||||

| D638 | Tensile Strength (psi) -lengthwise |

42,000 34,000 |

61,600 51,100 |

20,000 - |

45,000 38,000 |

43,000 37,000 |

| D790 | Flexural Strength (psi) -lengthwise -crosswise |

40,500 34,000 |

61,600 51,100 |

30,000 - |

75,000 65,000 |

80,000 70,000 |

| D790 | Flexural Modulus (Kpsi) -lengthwise -crosswise |

1,800 1,400 |

2,000 1,700 |

1,600 - |

2,700 2,400 |

3,000 2,700 |

| D256 | IZOD Notched Impact (ft-lb/in) -lengthwise -crosswise |

12.0 11.0 |

12.5 8.5 |

13.0 - |

14.0 12.0 |

12.0 9.0 |

| D695 | Compressive Strength (psi) | 55,000 | 65,000 | 50,000 | 65,000 | 63,000 |

| D785 | Hardness, Rockwell M | M110 | M115 | M105 | M110 | M112 |

| THERMAL | ||||||

| D696 | Coefficient of Linear Thermal Expansion (x 10-5 in./in./°F) -lengthwise -crosswise |

0.83 1.00 |

0.83 1.00 |

0.72 0.90 |

0.55 0.66 |

0.72 0.83 |

| - | Max Operating Temp (°F / °C) | 340 / 170 | 285 / 140 | 430 / 220 | 284 / 140 | 329 / 165 |

| C177 | Thermal Conductivity (BTU-in/ft²-hr-°F) (x 10-4 cal/cm-sec-°C) |

2.0 7.0 |

2.0 7.0 |

2.0 7.0 |

2.0 7.0 |

2.0 7.0 |

| UL94 | Flammability Rating | H-B | V-0 | H-B | H-B | H-B |

| ELECTRICAL | ||||||

| D149 | Dielectric Strength (V/mil) short time, 1/8" thick | 460 | 300 | 350 | 800 | 900 |

| D150 | Dielectric Constant at 1 MHz | 7.3 | 6.3 | 4.5 | 5.0 | 4.5 |

| D150 | Dissipation Factor at 1 MHz | 0.023 | 0.019 | 0.018 | 0.019 | 0.020 |

| D495 | Arc Resistance (sec) | 180 | 180 | 240 | 100 | 120 |

[G10/FR4 material chart]

Other Materials We Work With

Are you looking for another material? We have the ability to machine many different materials take a look below at some of the other plastics we work with.

Contact Upland Fab to Learn More About G10 Fiberglass Machining

Upland Fab has been providing top-flight plastics and composite machining in Southern California since 1970. Contact us for more information or get a quote on G10/FR4 electrical grade epoxy resin machining for your project.