Vespel® Machining

Vespel® per ASTM D6456 is considered one of the highest performing engineering plastics on the market today. The very properties that make this material such a performer also make it difficult to machine. Understanding the machining properties of various grades of Vespel® is critical to being able to produce a quality part. Upland Fab has decades of experience machining various grades of Vespel®.

Upland Fab's Vespel® Experience Saves Time & Money

Current users of Vespel® per ASTM D6456 and other Polyimides such as Meldin® already know there is a very high cost to these composite machining materials. This is why it is critical to choose a machining supplier with experience. Upland Fab’s experience enables parts to be machined with minimal scrap, these savings are passed on to the customer.

Properties of Vespel® Material

| TYPICAL PROPERTIES of Vespel | |||||||||||

| ASTM or UL test | Property |

|

|

|

|

|

|||||

| Filler Material | Unfilled | 15% Graphite | 40% Graphite | 10% PTFE, 15% Graphite | 15% Moly | ||||||

| PHYSICAL | |||||||||||

| D792 | Vespel® Density (lb/in³) (g/cm³) | 0.051 1.43 |

0.055 1.51 |

0.060 1.65 |

0.056 1.55 |

0.058 1.60 |

|||||

| D570 | Water Absorption of Vespel® 24 hrs @ 73°F (%) 48 hrs @ 122°F (%) |

0.24 0.72 |

0.19 0.57 |

0.14 0.42 |

0.21 0.49 |

0.23 0.65 |

|||||

| MECHANICAL | |||||||||||

| D638 |

Vespel® Tensile Strength, Ultimate @ 73°F (psi) |

12,000 6,000 |

9,500 5,500 |

7,500 3,400 |

6,500 3,500 |

8,200 - |

|||||

| D638 | Tensile Modulus (psi) | - | - | - | - | - | |||||

| D638 |

Tensile Elongation, Ultimate @ 73°F (%)@ 500°F (%) |

7.5 6.0 |

4.5 6.0 |

3.0 2.0 |

3.5 3.0 |

4.0 - |

|||||

| D790 | Flexural Strength of Vespel®, Ultimate @ 73°F (psi) @ 500°F (psi) |

16,000 9,000 |

16,000 9,000 |

13,000 6,500 |

10,000 5,000 |

11,000 5,500 |

|||||

| D790 |

Flexural Modulus @ 73°F (psi) |

450,000 250,000 |

550,000 370,000 |

700,000 400,000 |

450,000 200,000 |

475,000 270,000 |

|||||

| D695 | Compressive Strength, 10% strain @73°F(psi) | 19,300 | 19,300 | 16,300 | 14,800 | 18,500 | |||||

| D695 | Compressive Modulus (psi) | 350,000 | 420,000 | 475,000 | 300,000 | 350,000 | |||||

| D785 | Vespel® Hardness, Rockwell | E45-60 | E25-45 | E5-25 | E1-20 | E40-55 | |||||

| D256 | IZOD Impact Notched (ft-lb/in) | 0.8 | 0.8 | - | - | 0.4 | |||||

| THERMAL | |||||||||||

| D696 | Coefficient of Linear Thermal Expansion (x10-5 in./in./°F) |

3 | 2.7 | 2.1 | 3 | 2.9 | |||||

| D648 | Heat Deflection Temp (°F/°C) at 264 psi |

680 / 360 | 680 / 360 | - | - | - | |||||

| - | Max Continuous Operating Temp (°F/°C) | 500 / 260 | 500 / 260 | 500 / 260 | 500 / 260 | 500 / 260 | |||||

| C177 | Thermal Conductivity (BTU-in/ft²-hr-°F) (x10-4 cal/cm-sec-°C) |

2.0 6.9 |

6.0 20.7 |

12.0 41.3 |

5.3 18.3 |

3.2 11.0 |

|||||

| UL94 | Flammability Rating of Vespel® | V-0 | V-0 | V-0 | V-0 | V-0 | |||||

| ELECTRICAL | |||||||||||

| D149 | Dielectric Strength of Vespel® (V/mil) short time, 1/8" thick | 560 | 250 | - | - | - | |||||

| D150 | Dielectric Constant at 1 MHz | 3.55 | 13.2 | - | - | - | |||||

| D150 | Dissipation Factor at 1 MHz | 0.0034 | 0.0106 | - | - | - | |||||

| D257 | Volume Resistivity (ohm-cm) at 50% RH | 10^14 - 10^15 | 10^12 - 10^13 | - | - | - |

|||||

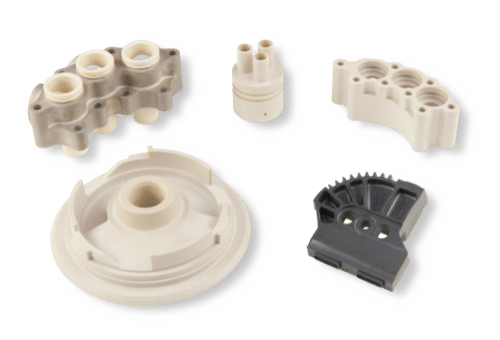

CNC Technologies for Machining Vespel® Polyimide Parts

Upland Fab employs the use of multi-axis machining when working with Vespel®. This application of technology is critical to ensuring the parts are machined correctly the first time with minimal handling and fixturing. Often times even the most complex parts are completed in a single operation.

By relying on Digital Product Definition, also referred to as Model-Based Definition or DPD/MBD processes, we are able to machine parts directly from our customers’ CAD models. As a result, the possibility of errors is greatly reduced – and so are costs. You won’t find high quality, low-cost Vespel® parts anywhere else.

Industrial Uses for Vespel Components

As one of the highest-performing engineering plastics in use today, Vespel is a popular choice across industries for an extensive range of productions.

- Medical: Vespel is exceptionally clean and highly resistant to chemicals, making it an ideal choice for medical productions. This can include manufacturing surgical caddies, medical devices, and surgical implements.

- Defense: Vespel’s many beneficial characteristics make it an excellent choice for rugged military and defense applications, including jet engines, heavy-duty off-road equipment, and more.

- Semiconductor & Electronics: As Vespel exhibits excellent dielectric properties and provides optimal electrical insulation, it is used to manufacture semiconductors and a variety of other electronic assemblies.

- Aerospace: Most jet engines contain Vespel parts as it provides excellent resistance to melting, flame, radiation, and more. It is also used to manufacture spacecraft components, bearings, fasteners, and much more.

Upland fab's Top-Flight Communication

Communication is essential for success. By offering a variety of Vespel® polyimide machining and fabrication services, we will ensure that projects move smoothly and swiftly. Moreover, every one of our clients works with a single point of contact, which means they experience reliable communication and a level of consistency that they won’t find anywhere else.

Other Materials We Work With

Are you looking for another material? We have the ability to machine many different materials take a look below at some of the other plastics we work with. Send us your project requirements and we'll be happy to personally connect with you and discuss your application in more detail!

|

|

||

|

|

||

|

|

|

|

Discover the advantages of partnering with Upland Fab

Upland Fab machines top-quality parts from Vespel® per ASTM D6456. Start a project today or give us a call at 909-986-6565 with any questions.