Torlon® Machining

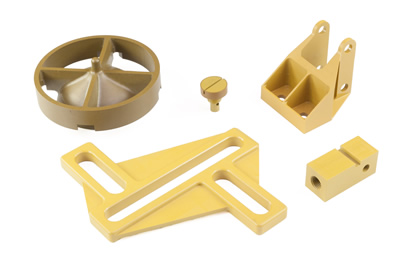

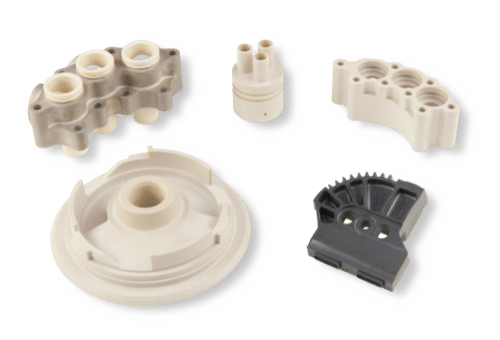

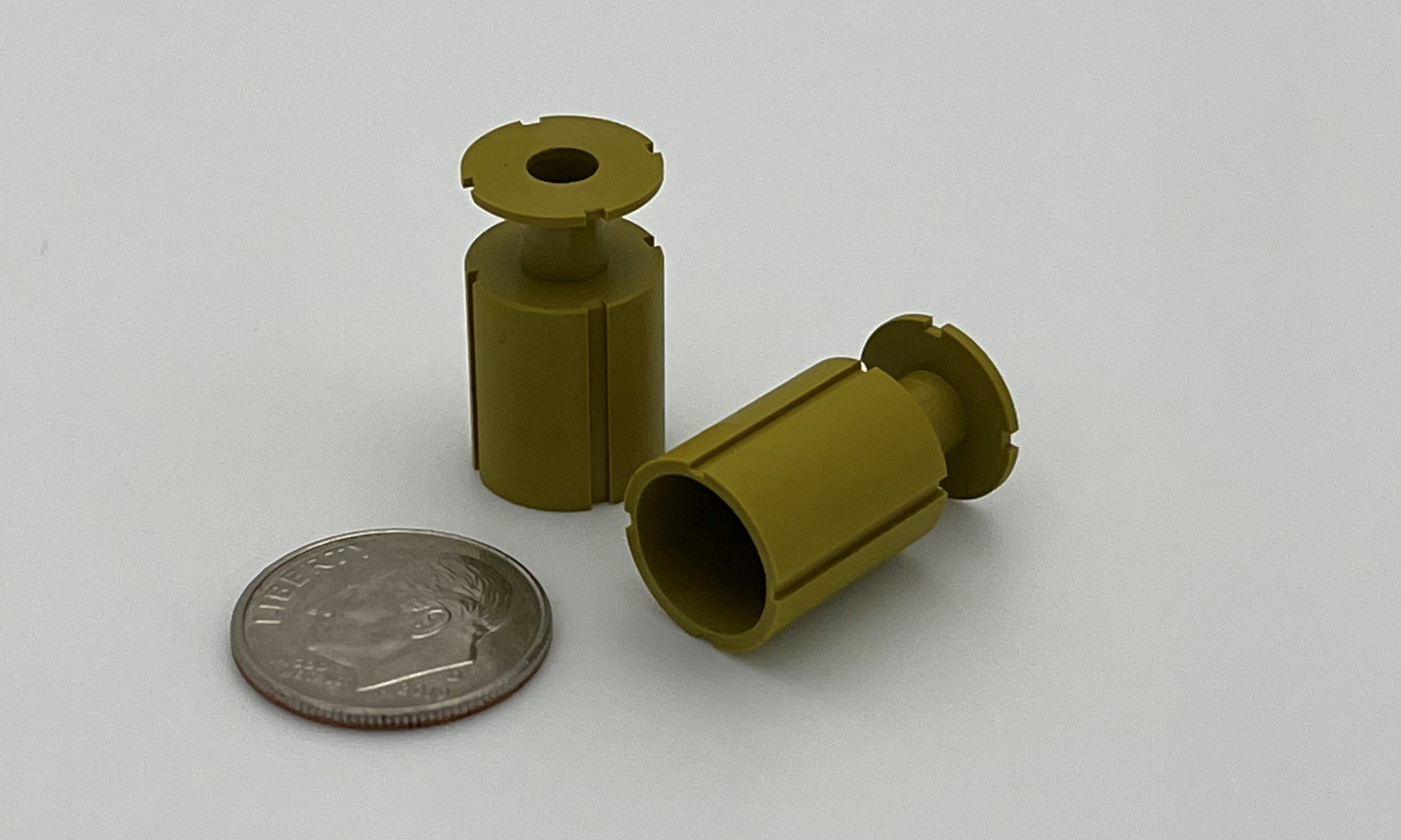

Precise machining of Torlon® can be very difficult especially in complex geometries involving large amounts of material removal. Upland Fab’s Engineers have over 2 decades of experience creating precise components in many grades of Torlon®. One of the many battles faced in machining Torlon® is managing the stresses in the material. Upland Fab’s internal annealing capabilities combined with the vast experience in machining Torlon® allow us to manage these stresses efficiently to produce stable parts the first time. Torlon® grades such as 4301 and 5530 can be extremely abrasive, wearing out tools at a rapid pace. Upland Fab’s engineers understand this up front and plan accordingly. This helps the customer get their parts on time and to print by removing any potential delays.

Performance-Leading Torlon® Polyamide-Imide (PAI)

Torlon® (Polyamide-Imide or PAI) is considered one of the highest performing engineering plastics on the market today. Torlon® exhibits excellent dimensional stability with low creep at continuous operating temperatures of 500°F. Torlon® is used throughout many industries such as aerospace for satellite components; it’s used in the semiconductor industry for socket assemblies; it’s used in the fluid transfer industry for pump components and valve seals.

Properties of Torlon® Material

| TYPICAL PROPERTIES of Torlon® | |||||||||||

| ASTM or UL test | Property |

|

|

|

|

|

|||||

| Elect. Grade | Bearing Grade | Glass-Filled | Extruded | Compression Molded | |||||||

| PHYSICAL | |||||||||||

| D792 | Torlon® Density (lb/in³) (g/cm³) | 0.051 1.41 |

0.052 1.45 |

0.059 1.61 |

0.058 1.6 |

0.058 1.61 |

|||||

| D570 | Water Absorption of Torlon®, 24hrs (%) |

0.4 |

0.4 |

0.3 |

0.3 |

0.3 |

|||||

| MECHANICAL | |||||||||||

| D638 |

Torlon® Tensile Strength (psi) |

18,000 |

12,000 |

15,000 |

23,000 |

15,000 |

|||||

| D638 | Torlon® Tensile Modulus (psi) | 600,000 | 800,000 | 900,000 | 1,000,000 | 900,000 | |||||

| D638 |

Tensile Elongation at Break (%) |

10 |

3 |

3 |

4 |

3 |

|||||

| D790 | Flexural Strength of Torlon® (psi) |

24,000 |

23,000 |

20,000 |

30,000 |

20,000 |

|||||

| D790 |

Flexural Modulus (psi) |

600,000 |

800,000 |

900,000 |

980,000 |

900,000 |

|||||

| D695 | Compressive Strength of Torlon® (psi) | 24,000 | 19,300 | 16,300 | 14,800 | 18,500 | |||||

| D695 | Compressive Modulus (psi) | 700,000 | 950,000 | 600,000 | 700,000 | 600,000 | |||||

| D785 | Torlon® Hardness, Rockwell | E80 (M120) | E70 (M106) | E85(M125) | E90 | E85(M106) | |||||

| D256 | IZOD Impact Notched (ft-lb/in) | 2 | 0.8 | 0.7 | 1 | 0.7 | |||||

| THERMAL | |||||||||||

| D696 | Coefficient of Linear Thermal Expansion (x10-5 in./in./°F) |

1.7 | 1.4 | 2.6 | 0.9 | 2.6 | |||||

| D648 | Heat Deflection Temp (°F/°C) at 264 psi |

532 / 278 | 534 / 279 | 520 / 271 | - | 520 / 271 | |||||

| - | Max Continuous Operating Temp of Torlon® (°F/°C) | 500 / 260 | 500 / 260 | 500 / 260 | 500 / 260 | 500 / 260 | |||||

| C177 | Thermal Conductivity (BTU-in/ft²-hr-°F) (x10-4 cal/cm-sec-°C) |

1.8 6.2 |

3.7 12.8 |

2.5 8.61 |

2.5 8.6 |

2.5 8.6 |

|||||

| UL94 | Flammability Rating of Torlon® | V-0 | V-0 | V-0 | V-0 | V-0 | |||||

| ELECTRICAL | |||||||||||

| D149 | Dielectric Strength of Torlon® (V/mil) short time, 1/8" thick | 580 | - | 700 | 700 | - | |||||

| D150 | Dielectric Constant at 1 MHz | 4.2 | 6 | 6.3 | 6.3 | - | |||||

| D150 | Dissipation Factor at 1 MHz | 0.026 | 0.037 | 0.022 | 0.05 | - | |||||

| D257 | Volume Resistivity (ohm-cm) at 50% RH | 10^16 | 10^13 | 10^13 | 10^13 | 10^13 | |||||

Using CNC Technologies for Machining Torlon® Plastic

Using CNC Technologies for Machining Torlon® Plastic

Upland Fab employs the use of multi-axis machining when working with Torlon®. This application of technology is critical to ensuring the parts are machined correctly the first time with minimal handling and fixturing. Often times even the most complex parts are completed in a single operation. Managing moisture absorption is critical to holding precise tolerances in Torlon®, Upland Fab’s ability to dry machine (no coolant) Torlon® reduces the effect of moisture absorption.

The Digital Product Definition, also referred to as Model-Based Definition or DPD/MBD processes in place at our facility allow us to make complex Torlon® parts directly from a customer supplied CAD model. The result? Accurate and cost-effective parts.

Follow Your Project Every Step Of The Way With Upland Fab's Top-Flight Communication

Our ability to machine Torlon® is just one of the things that set us apart from other manufacturers. By prioritizing communication, we’re able to offer our clients constant updates and peace of mind as their projects move forward. As our customer, you’ll work with a single point of contact who will work closely with you – every step of the way.

Other Materials We Work With

Are you looking for another material? We have the ability to machine many different materials take a look below at some of the other plastics we work with.

|

|

||

|

|

||

|

|

|

|

Contact Upland Fab today to learn more about Torlon® Machining.

Providing Top-flight Plastics & Composite Machining in Southern California Since 1970. Contact us today for more information or Get a Quote to start a project. We are looking forward to hearing from you!

Contact Us Request A Quote